構(gòu)電影院.jpg)

Steel Cinema

1.Cinema

SBS's goal is to provide high-quality prefabricated steel structure warehouse and cinema to customers and create mutual benefits.

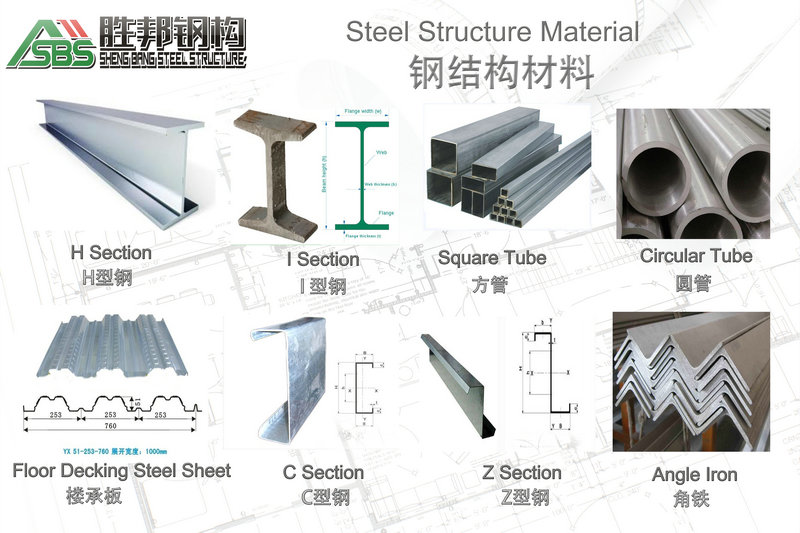

2.The detail material for the steel structure

The steel structure material is included the H section,I section,Square tube,Circular Tube,Floor decking steel sheet,C section,Z section,Angle iron , Steelbar ,Steel plate .

1)H section steel

H type steel is an economic efficient section material with optimized cross section area allocation and more reasonable ratio of strength to weight. It is named because of its letter "H" cross section. Since its different parts are of orthogonal configuration, h-beam has advantage of good bending capacity, simple construction, cost saving and structure light weight etc., has been widely used.

2)H-beam is divided into:

The flange wide type (HW)

The flange middle type (HM)

The narrow flange type (HN)

Thin-wall h-beam type (HT)

H section steel pile type (HU)

3.Product detials

| 1.Opinions | 1)We can supply all kinds of steel structures, steel building, metal building, modular house, steel frame for warehouse, workshop, garage etc, steel beams, other riveting and welding parts. |

| 2)We can also make and develop new parts according to customers' drawings and detailed dimensions. | |

| 2. Specifications | 1) Size: MOQ is 200m2, width X length X eave height, roof slope |

| 2) Type: Single slope, double slope, muti slope; Single span, double-span, Multi-span, single floor, double floors | |

| 3) Base: Cement and steel foundation bolts | |

| 4) Column and beam: Material Q345(S355JR)or Q235(S235JR) steel, all bolts connection! Straight cross-section or Variable cross-section | |

| 5) Bracing: X-type or V-type or other type bracing made from angle, round pipe, etc | |

| 6) C or z purlin: Size from C120~C320, Z100~Z200 | |

| 7) Roof and wall panel: Single colorful corrugated steel sheet 0.326~0.8 mm thick, (1150 mm wide), or sandwich panel with EPS, ROCK WOOL, PU etc insulation thickness around 50 mm ~ 100 mm. | |

| 8) Accessories: Semi-transparent skylight belts, Ventilators, down pipe, Galvanized gutter, etc | |

| 9) Surface: Two lays of Anti-rust Painting | |

| 10) Packing: Main steel frame without packing load in 40'OT, roof and wall panel load in 40'HQ | |

| 3. Design Parameters | If you need we design for you, pls supply us the following parameter together with detail size |

| 1) Live load on roof (KN/M2) | |

| 2) Wind speed(KM/H) | |

| 3) Snow load (KG/M2) | |

| 4) Earthquake load if have | |

| 5) Demands for doors and windows | |

| 6) Crane (if have) , Crane span, crane lift height, max lift capacity, max wheel pressure and min wheel pressure! |

4.Description of steel structure building

1)Certification:SGS Standard,GHD Standard,ISO9001:2000

2)Steel structure design common norms are as follows:

"Cold-formed steel structure technical specifications" (GB50018-2002)

"Construction Quality Acceptance of Steel" (GB50205-2001)

"Technical Specification for welded steel structure" (JGJ81-2002, J218-2002)

"Technical Specification for Steel Structures of Tall Buildings" (JGJ99-98)

3)Commonly used steel grades and performance of steel

Carbon structural steel: Q195, Q215, Q235, Q255, Q275, etc.

High-strength low-alloy structural steel

Quality carbon structural steel and alloy structural steel

Special purpose steel

4) Wall & roof can be used by steel sheet, EPS sandwich panel, rock wool sandwich panel & PU sandwich panel.

5.Transportation:

Steel structure is mainly composed of steel column, steel beam, steel frame and the rigid support and so on, so steel structure component volume is larger, The mainly transportation for export is as follow:

1)40'HQ and 40'open top container

In general, after customer order, our engineering technology department design the steel structures will be according to the 40 'HQ and 40' open top container inside size to design the shipment, in most cases, we use 40 'HQ and 40' open top shipping container shipment to pack steel structures.

2)Break bulk

At special circumstances, some large construction size will be more than 40 'HQ and 40' open top containers internal dimensions, we suggest customer use trucks, flatbed trailer etc to transport the large construction component to the pier from the factory, then ship by port lifting, so while booking space,customers should book the break bulk. We will cooperate with the customer to provide them the size and weight of the goods, in order to book a reasonable space.

Remark:

When components are shipped to the site, due to various reasons of transport may cause component deformation (generally for bending, damage to the paint film, etc.), can be in the scene to correct, at present the correction method is generally divided into cold straightening and hot straightening.

For bending component, do the mechanical gagging with oil pump, also can use flame (C2H2 and pure oxygen mixed) to the hot straightening, after correction, the paint film that damaged must be repaired.

Contact way

1)FOSHAN SHENGBANG STEEL STRUCTURE CO., LTD

2)Add:Pingtang Industrial Park, Shipeng Village, Shishan Town, Nanhai District,

3)Foshan, Guangdong Province, China

4)Tel:0086-757-63323396/0086-757-18900873268 Fax:0086-757-81196682