Hoisting process

Positioning --- Calibration Height --- Column Top Bolt Embedded --- Calibration Height - Elastic Line - Column Installation - Steel Beam Installation - Secondary Structure Installation --- --Welding----Repainting----Completion

Steel column installation process

A,Lifting of steel columns

1.Re-test the foundation, including the exposed length of the anchor bolt, the displacement deviation of the anchor bolt center line to the reference line, the distance between the anchor bolts, and the foundation elevation. The unqualified ones can be handled before lifting.

2.In order to control the installation elevation of the column, a 500mm position is also marked on the visible cross section of the column in advance for fine-tuning and correction of the elevation during installation. Install the steel column on the basis of qualified retest, first tie the column with a single steel wire rope, and choose the position of the lifting point at a position 1/3 of the length of the column from the end of the column. The column is lifted by the rotation method, and the steel column is lifted and sent to the installation position. The lashing place should be padded.

B, the correction of the steel column

1.Draw the center line in advance on the visible surface of the column, and then use the theodolite to adjust the verticality of the column in two mutually perpendicular directions.

2.Control the verticality of the column by measuring the distance between the inner side of the column and the control line on the building.

3.The adjustment of the elevation, axis and verticality deviation of the column are related to each other, and the correction work will be completed when all the standards are met.

Steel beam installation process

Unload the steel beams to the vicinity of each column, hoist them to the floor with a car, and then install them by mast cranes. The main beams with some heavy components can be platform craned with car cranes. The secondary beam can be installed with a self-made wheeled crane (5t). Starting from the third zone, the main girder, the secondary girder and then the purlin, the steel girder shall be hoisted by masts one by one according to the number. Only when the two ends of the girder are fastened with bolts (or spot welded firmly), the hooks can be loosened and the others are hoisted in sequence Steel beams. Weld after passing the inspection.

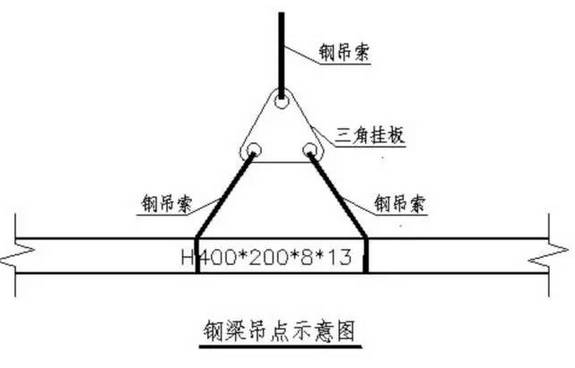

The lashing and hoisting points of steel beams are particularly important. Steel poles can be used when the steel beams are too long. There are many steel beams in this project with a maximum length of about 20m. A triangular hanging plate is used to enlarge the distance between the steel ropes to increase the angle of the steel ropes. Require. Schematic diagram of steel beam lashing.